The DSP Distributor Valve is an integrated progressive distributor, particularly suitable for applications with limited space. The design of the DSP Distributor Valve allows for precise and uniform distribution of lubricants, ensuring reliable operation of machinery under various working conditions. Here are the main functions and roles of the DSP Distributor Valve:

High Pressure Resistance: The DSP Distributor Valve can operate at a maximum pressure of up to 350 bar (5076 psi), suitable for high-pressure environments. Its design withstands harsh working conditions, ensuring reliable performance under high pressure.

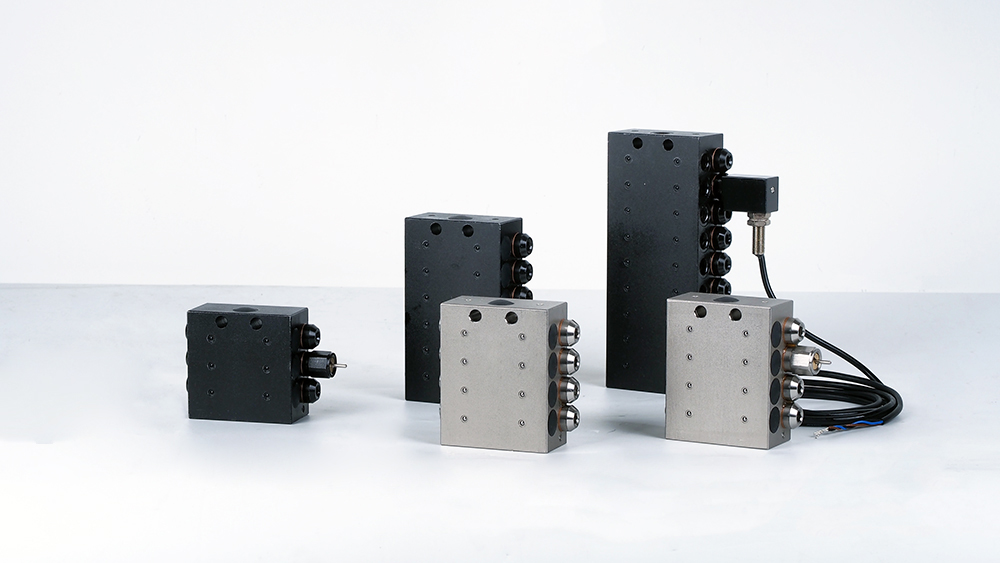

Multi-Outlet Design: The DSP Distributor Valve is available in versions with 6 to 22 outlets, each with a discharge of 0.2 cm³ per cycle. This design allows the distributor to be adjusted according to specific application needs, meeting the lubrication requirements of different equipment.

Flexible Outlet Combining: By installing plugs, any outlet can be connected to the adjacent outlet, achieving flow stacking. This design increases the distributor's flexibility, accommodating more lubrication needs.

Corrosion Resistance: The DSP Distributor Valve is made from nickel-plated carbon steel, providing excellent corrosion resistance and suitability for various harsh environments.

Strong Temperature Adaptability: The operating temperature range of the DSP Distributor Valve is -40°C to 200°C, maintaining good performance under extreme temperature conditions.

Broad Lubricant Compatibility: The distributor is compatible with Oil 46 - NLGI-2#, meeting the lubrication needs of different equipment.

Improving Equipment Performance: By distributing lubricants evenly and accurately, the DSP Distributor Valve ensures proper lubrication of all points, reducing wear and failures, and enhancing the reliability and lifespan of the equipment.

Reducing Maintenance Costs: Accurate lubricant distribution reduces waste and lubricant usage, lowering maintenance costs. Additionally, the high reliability of the distributor reduces downtime and repair expenses.

Easy Operation Monitoring: The DSP Distributor Valve can be equipped with visual or electronic monitoring devices. By removing a plug and installing a corresponding monitoring device, users can easily monitor the lubrication process and ensure the system is functioning properly.

Suitable for Various Applications: Due to its compact design and flexible outlet configuration, the DSP Distributor Valve is particularly suitable for applications with limited space, such as engineering machinery, agricultural machinery, wind power equipment, heavy equipment, and vehicle lubrication systems.

Enhancing Safety: The built-in check valve ensures the accuracy of each lubricant filling, preventing backflow of the lubricant and ensuring the safety and stability of the system.

In conclusion, the DSP Distributor Valve plays a crucial role in centralised grease lubrication system of machinery with its high-pressure operation capability, multi-outlet design, flexible outlet combining, excellent material selection, and broad lubricant compatibility. It not only enhances equipment reliability and efficiency but also significantly reduces maintenance costs, providing reliable centralized lubrication system for various industrial applications.