The Need for Lubrication in Harbor Facilities

Port equipment, typically located in special locations such as seashores or docks, is large and requires a significant amount of lubricant for smooth operation. The maintenance of these machines can be challenging due to their size and the harsh environmental conditions they operate in. Progressive lubrication system plays a crucial role in reducing friction between moving parts, preventing wear and tear, and ensuring the longevity of the equipment.

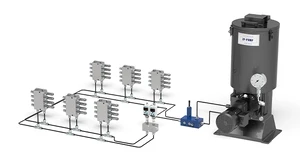

The Benefits of CisoLube GP212 Series Products

The CisoLube GP212 series products are particularly suitable for port equipment due to their large capacity, smooth operation, low noise, and low failure rate. These lubrication products are easy to install and maintain, reducing the time and effort required for equipment maintenance. Furthermore, each pump head in the GP212 series can be easily adjusted to regulate the flow rate, providing flexibility and convenience in lubrication management.

Application Scope in Harbor Facilities

The CisoLube GP212 series products can be applied to a wide range of port equipment, including gantry cranes, bridge cranes, ship lifters, suspension cranes, container cranes, unloaders, and boom cranes. The lubrication products ensure the smooth operation of these machines, reducing the risk of equipment failure and downtime. This not only improves the efficiency of port operations but also extends the service life of the equipment, providing significant cost savings in the long run.

In conclusion, the application of grease distributor and lubricating pumps, particularly the CisoLube GP212 series, is essential in the maintenance and operation of port equipment. These products provide a practical and efficient solution to the challenges posed by the size and operating conditions of port equipment, ensuring their longevity and optimal performance.

Contact CisoLube for Centralised Grease Lubrication System

CN

CN

EN

EN

ru

ru  fr

fr  de

de  es

es  pt

pt  ar

ar  hi

hi  id

id  tr

tr  it

it  pl

pl  nl

nl