The Importance of Lubrication in Automation Equipment

The use of lubrication products in automation equipment is crucial for the smooth operation and longevity of the machinery. Regular monitoring and maintenance of lubrication work are necessary to ensure the quality and supply of lubricants, as well as to monitor indicators such as viscosity, contamination level, and residual amount.

Advanced Lubrication Products for Automation Equipment

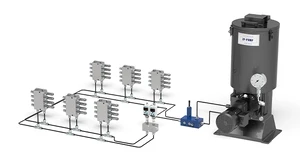

The CisoLube GM and GT-MAX series products are designed with a visual pump body that allows for intuitive monitoring of the grease condition. The front end of the distributor can be equipped with a filter to effectively filter out impurities in the oil. Additionally, the end pressure detection switch can provide timely feedback on lubrication failures in the equipment. These features make these lubrication products ideal for use in automation equipment.

Scope of Application in Automation Equipment

These single line lubrication system and progressive lubrication system find wide application in various types of automation equipment. They are used in robotic arms, automatic winding machines, automatic welding machines, automatic assembly machines, automatic testing machines, automatic slitting machines, automatic laser marking machines, automatic sealing machines, and automatic screw locking machines, among others.

In conclusion, the application of lubricating pumps and grease distributor in automation equipment is essential for maintaining the efficiency and durability of the machines. Advanced lubrication products like the CisoLube GM and GT-MAX series, with their innovative features, provide effective lubrication solutions for a wide range of automation equipment. Regular monitoring and maintenance of these lubricants ensure the optimal performance of the equipment and significantly extend their service life.

Contact CisoLube for Centralised Grease Lubrication System

CN

CN

EN

EN

ru

ru  fr

fr  de

de  es

es  pt

pt  ar

ar  hi

hi  id

id  tr

tr