The Demand for Lubrication in Steel Metallurgy Equipment

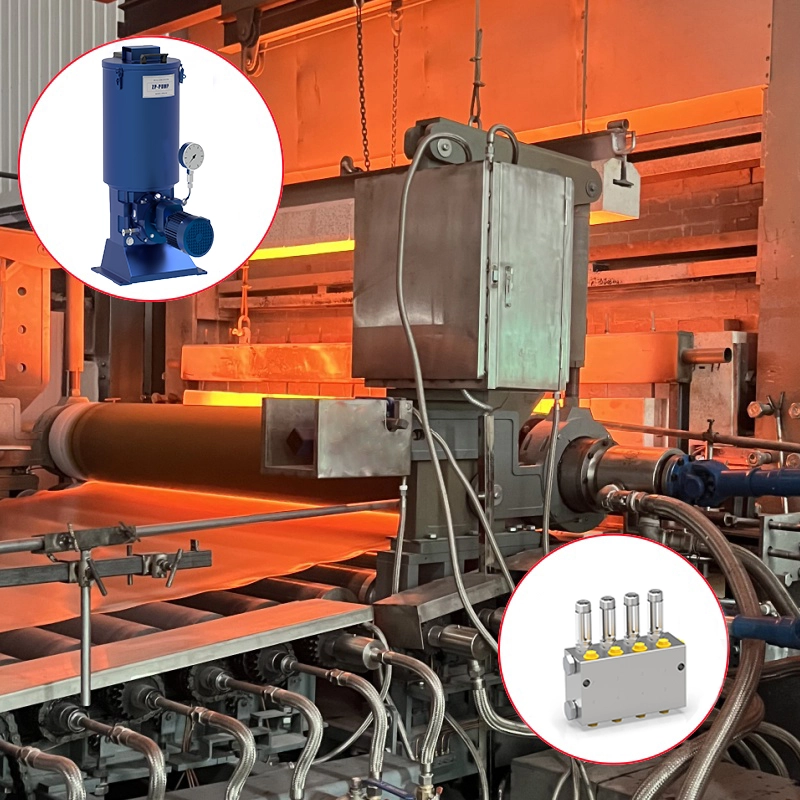

Steel metallurgy equipment often operates under harsh conditions such as high temperature, high pressure, and high load, requiring a large amount of lubrication. The equipment's key parts, such as bearings, gears, and chains, are subjected to intense friction and wear, necessitating effective lubrication to ensure smooth operation and prolong equipment life.

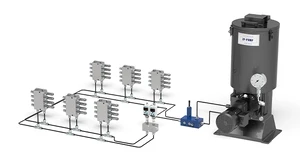

The Role of ZP Series Dual-Line Lubrication System

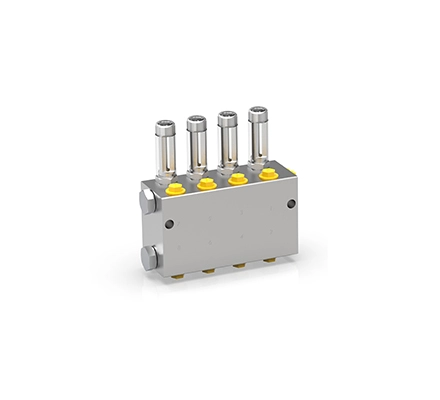

The ZP series dual-line lubrication system from CisoLube can be installed in the critical parts of the equipment. This system can provide lubricant to the equipment through two lubrication pipelines simultaneously, ensuring that the lubricant can fully lubricate the key parts of the equipment. The dual line lubrication systems ensures a continuous supply of lubricant, reducing the risk of equipment failure due to inadequate lubrication.

Lubrication System Application Scope in Steel Metallurgy

The ZP series dual-line lubrication system is versatile and can be applied to various steel metallurgy equipment. These include steelmaking equipment, rolling mills, casting machines, injection molding machines, and presses. By providing consistent and effective lubrication, the system helps to maintain the efficiency of these machines, reduce downtime, and extend their service life.

In conclusion, lubricating pumps play a vital role in the operation of steel metallurgy equipment. The ZP series dual-line lubrication system from CisoLube lubrication system manufacturer, in particular, provides a reliable solution for maintaining the smooth operation of these machines under harsh conditions. By ensuring adequate lubrication, it contributes to the overall efficiency and longevity of the equipment.

Contact CisoLube for Centralised Grease Lubrication System

CN

CN

EN

EN

ru

ru  fr

fr  de

de  es

es  pt

pt  ar

ar  hi

hi  id

id  tr

tr