In the application of mining conveyor belts, stable and continuous lubrication is crucial for the normal operation of equipment, especially in high-dust and high-load environments. The combination of CISOLUBE's GP212 multi-point lubrication pump and DSP distributor provides a specialized lubrication solution for mining conveyor belts. This system ensures that each lubrication point receives continuous and precise lubrication support under harsh conditions.

Mining conveyor belt systems typically include key components such as rollers, bearings, and drive chains, which operate frequently under high loads. The combination of the GP212 multi-point lubrication pumps and DSP distributor ensures accurate distribution of lubricants, thereby extending equipment lifespan, reducing downtime, and increasing production efficiency.

High Pressure Output and Multi-Point Lubrication

Number of Lubricant Outlets: The GP212 supports 1 to 12 lubricant outlets, covering multiple lubrication points within the conveyor belt system to meet its complex lubrication needs.

Output Volume per Outlet (KR12): Adjustable from 500-1500 ml/h (based on a 50Hz operating frequency), ensuring uniform lubrication across all conveyor components and preventing wear due to uneven lubrication.

Powerful Technical Specifications

Maximum Working Pressure: 35MPa, sufficient to meet the high-load operational requirements of mining conveyor belts.

Oil Tank Capacity: 30L, with an optional mechanical level indicator for monitoring lubricant usage and reducing maintenance frequency.

Motor Power: 0.75KW, ensuring stable operation over extended periods.

Power Supply Connection: Supports 220VAC/380VAC/660VAC, flexibly adapting to various industrial power supply needs.

Durable Design and Environmental Adaptability

Protection Level: IP55, with dust and waterproof design suitable for harsh mining environments.

Applicable Lubricants: Compatible with NLGI Grade 3 grease, accommodating high viscosity requirements to enhance lubrication effectiveness.

Reduction Ratio: 60:1, ensuring stable lubricant output under varying loads.

Explosion-Proof Rating: EXdIIBT4, suitable for high-risk areas with flammable gases, ensuring safety.

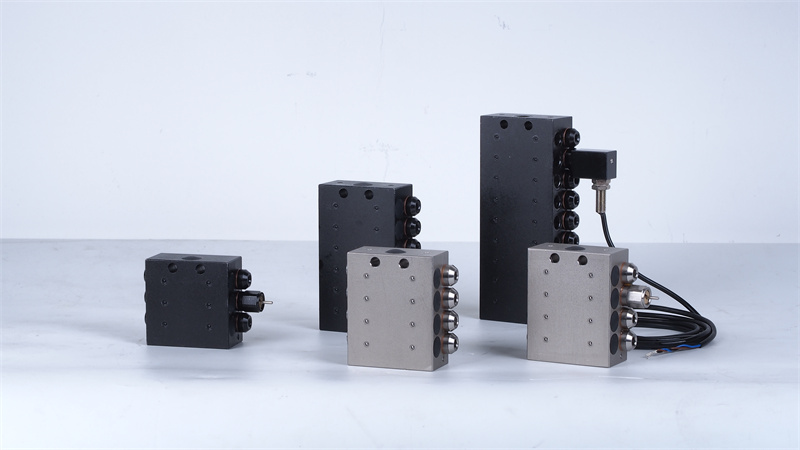

Precise Distribution Under High Pressure

Technical Parameters: Supports working pressures from 20 to 350Bar, enabling stable delivery of lubricants to each lubrication point over long distances and complex layouts.

Lubricant Distribution: Single discharge volume of 0.2ml, suitable for NLGI Grade 2 grease and lubricating oils of various viscosities. Its precision design ensures stable distribution of lubricants at long distances.

Flexible Outlet Configuration

Number of Outlets: DSP distributors can have between 6 and 22 outlets, allowing users to flexibly choose configurations based on the number of lubrication points. The modular design makes it easy to install and expand to meet the complex requirements of conveyor belts.

Monitoring and Alarm Functions

The DSP distributor is equipped with a visible pointer and electronic sensors that can monitor lubrication status in real-time. When a blockage occurs, the system automatically alarms to prevent uneven lubrication that could lead to equipment failure.

Conclusion: The Ideal Choice of GP212 Pump and DSP Distributor

The lubrication system manufacturer CISOLUBE's GP212 multi-point lubrication pump and DSP distributor provide an efficient and reliable lubrication solution for mining conveyor belts. With a high-pressure output of 35MPa, IP55 protection level, adjustable lubricant discharge volume, and explosion-proof design, they perform exceptionally well in harsh environments. This combination not only reduces maintenance costs but also enhances equipment operating efficiency, making it the ideal lubrication solution for the mining industry.