In modern agriculture, balers play a critical role in efficiently baling and transporting hay and straw. To ensure the long-term, efficient operation of balers, choosing the right lubrication system is crucial. Traditional manual lubrication not only consumes time but often leads to either under-lubrication or over-lubrication due to the difficulty in controlling the timing and amount of lubrication accurately. This can affect the machine's lifespan and productivity. Therefore, automatic lubrication systems have become the ideal choice for maintaining balers.

Automatic lubrication systems can provide precise lubrication to key components based on the machine’s operating status and pre-set lubrication cycles. This effectively reduces wear on bearings, gears, and other moving parts, extending the equipment’s service life.

Manual lubrication typically requires regular shutdowns for maintenance, whereas automatic lubrication systems work continuously while the equipment is in operation, minimizing downtime and maximizing productivity.

Automatic lubrication systems control the amount of lubricant used, preventing wastage and saving on lubrication material costs. Additionally, by reducing wear and the likelihood of breakdowns, maintenance and replacement costs are significantly lowered.

Manual lubrication, especially during machine operation, can present safety risks. Automatic lubrication systems are fully automated, eliminating the need for manual intervention and greatly reducing operational safety hazards.

Fully Automated Control: With a built-in intelligent controller, the system automatically adjusts the lubrication frequency and quantity based on the equipment’s usage, ensuring optimal lubrication of all baler components.

Reliable Sealing Design: Dust- and waterproof, these systems are designed to withstand harsh outdoor environments, especially in dusty and humid conditions common in fields.

Modular Design, Easy Maintenance: The system consists of multiple modules, making installation, disassembly, and maintenance easy, reducing maintenance difficulty and costs.

Recommended Automatic Lubrication System for Balers

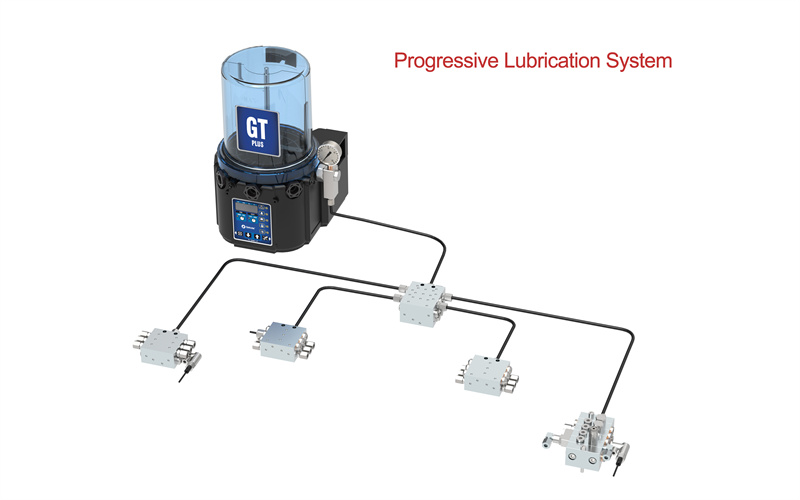

To meet the high-intensity operational needs of balers, we recommend the GT PLUS Lubrication Pump, a high-performance system designed for heavy-duty machinery with the following benefits:

Precision Lubrication: Utilizing advanced lubrication control technology, the GT PLUS pump ensures that each component receives the right amount of lubrication at the right time, effectively extending equipment life.

Efficient Delivery: The GT PLUS pump employs high-pressure technology to ensure that lubricant is smoothly delivered to all lubrication points, even to components that are located at a distance.

Durable and Robust: Its sturdy design is built for durability, making it well-suited for harsh working environments, especially in the high-dust and complex conditions found in agricultural fields.

The efficient operation of balers depends on a reliable lubrication system. The application of automatic lubrication systems not only increases operational efficiency and extends equipment life but also saves farmers on maintenance costs. As agricultural mechanization continues to develop, the GT PLUS Lubrication Pump offers an excellent lubrication solution for balers, ensuring that your equipment performs at its best during demanding field operations.