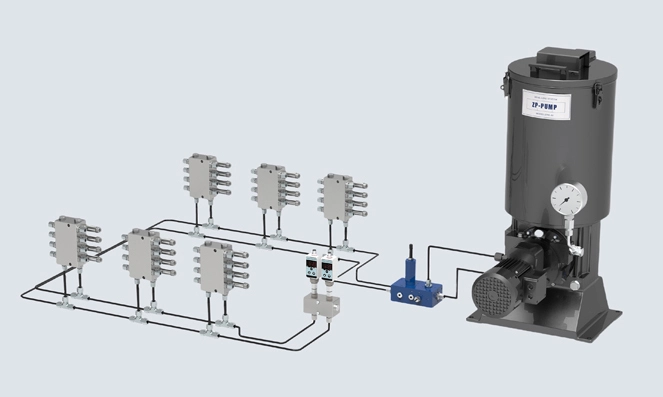

CISO autmotic dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities. These central dual line lubrication systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump via a change-over valve at up to 400 bar (5 800 psi) Branch lines, along the main lines, are connected with dual-line metering devices to supply a large volume of lubricant to the lubrication points Within large dual-line systems, end-of-line pressure switches are used to control and monitor the centralized dual line lubrication systems.

Do not install or remove the metering devices when the system is under pressure or the pump in operation.

Always protect the centralized dual line lubrication systems connected to the pump with a pressure reducing valve.

lncorrect operation may lead to damage resulting from insufficient or excessive lubrication of bearings or lubrication points.

Your own alterations or modifications of installed automatic dual line lubrication systems should only be carried out if approved with the manufacturer or his appointed dealer. Contact Cisolube centralized grease lubrication system for detailed information.

For all work at the metering device, observe extreme cleanliness.

Attach the metering devices to even surfaces without tension. When base plates are used, first weld the base plates without the metering devices and then attach the metering devices onto them.

Protect the metering devices from dust and influences of heat (observe the maximum admissible operating temperatures).

The metering devices must be easily accessible for . check and installation work.

Before connecting the feed lines to the metering devices, fill them with lubricant.

when connecting the main lines take care to always connect the same line (l or ll) to the same metering device inlet.

This makes it easier to check of the metering device because all indicator pins are either in or out after each cycle.

A、ZP01/02 Lubrication Pump

B、ZP08/14/24 Lubrication Pump

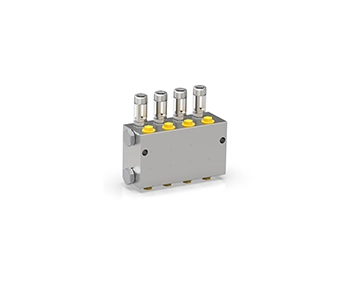

DSG Dual-line Metering Devices

DSL Dual-line Metering Devices

DSKH Metering Devices

Accessories

WP-C Electric Change-Over Valve

DU-C Hydraulic Change-Over Valves

MC-ⅠSystem Control Box

EPW End-of-line Pressure Switches

A dual-line lubrication system operates using two main supply lines that alternately pressurize to deliver lubricants, such as grease or oil, to multiple lubrication points. When the first line is pressurized, lubricant is dispensed to half of the lubrication points, while the second line remains depressurized. Once the desired amount of lubricant is delivered, the system switches, pressurizing the second line and depressurizing the first. This alternating process ensures reliable and consistent lubrication even in large or complex systems. Dual-line systems are highly efficient, can handle long distances and numerous lubrication points, and are ideal for harsh industrial environments.

Choosing the right dual-line lubrication system involves evaluating several key factors. First, assess the specific lubrication requirements of your machinery, including the type and number of lubrication points. Consider the operating conditions, such as temperature, load, and environmental factors, to ensure the system can withstand these challenges. Opt for systems with reliable construction and compatibility with the lubricants you use. Look for features like automated monitoring and control to facilitate maintenance. Ease of installation, scalability, and the availability of support and spare parts are also important. Consulting with experts and reviewing industry-specific case studies can help make an informed decision.

| Feature | Progressive Lubrication Systems | Single-Line Lubrication Systems | Dual-line Lubrication Systems | Chain Lubrication Systems |

| Definition | Progressive lubrication system is an efficient lubrication system used for mechanical equipment, providing lubricant progressively to different parts of the equipment to ensure each part receives an adequate amount of lubrication. |

The lubrication pump automatically delivers lubricant to the lubricant dispenser via a single supply line. Each dispenser serves only one lubrication point and can be adjusted to provide the exact dose of grease or oil required. |

Dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump. |

Chain lubrication system is a system used to protect and maintain chains of mechanical equipment. It works mainly by providing the right amount of lubricant to reduce chain friction and wear, and to maintain chain flexibility and operating efficiency. A chain lubrication system usually includes a tank, lines, and brushes. These components work together to ensure that the chain surface is always properly lubricated, prolonging the life of the chain and drive system, reducing maintenance costs, and improving equipment reliability and efficiency. |

| Basic Components | A —GT auto lube pump B —GM auto lubrication pump C—GP203 lubrication pump D—GP205 lubrication pump E—GT-X lubrication pump F—GT-HEAVY lubrication pump G—GP212 lubrication pump Outlet relief valve elements Main line Filter Pressure switch Progressive distributor(1generation) Progressive distributor(2generation) Progressive distributor(2generation) Progressive distributor(3generation) Function control Fault Monitoring Pipes and hoses Line to the lubrication point Controller |

A — C-flow lubrication pump D — GTS single line lubrication pump E — GMS electric lubrication pump F — GT-MAX lube grease pump Return solenoid valve assembly Pressure gauge Pipelines Filter Tee branching pleces Pipe clamps Four branching pleces Volumetric distributor Check device(pressure switch) Line to the lubrication point Controller |

DSG Dual-line Metering Devices DSL Dual-line Metering Devices DSKH Metering Devices WP-C Electric Change-Over Valve DU-C Hydraulic Change-Over Valves MC-ⅠSystem Control Box EPW End-of-line Pressure Switches |

Oil Tank Brushes High-Pressure Flexible Pipe |

| Working Principle | The lubricant is pumped through the main lines to the progressive distributor with the pump. The lubricant is elivered "progressively" to the friction point. The circulation of a progressive distributor is monitored optically or electrically. |

The dosing values are impinged on the main line with the pump – dynamically operating metering valves with a pressure surge, static operating dosing elements with slow pressure build-up. These thus transfer the respective quantity of the lubricant to the friction point.During the following relief phase, the lubricant is restacked in the dosing valves for the next lubrication process. |

CISO dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities. These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump via a change-over valve at up to 400 bar (5 800 psi) Branch lines, along the main lines, are connected with dual-line metering devices to supply a large volume of lubricant to the lubrication points Within large dual-line systems, end-of-line pressure switches are used to control and monitor the system. |

The chain lubrication system transfers the lubricant from the storage tank to the brushes through the lubrication pump, and through the brushes the lubricant is applied to the chain to form a lubricating film, which reduces the chain friction and wear. |

| Advantages | Compact, flexible kit Monitored function Channels flow through completely Wide range of use |

Connecting numerous lubrication points Smallest dosing quantities Compact construction For oil or fluid grease Low cost and high efficiency Easy assembly |

Reliable Simple to service Ultrasonic low- and high-level control options Built-in lubricant filter |

Compact structure and easy expansion No need for a distributor The pipes are smooth and have no residue Adjustable displacement |

CISO-Your Partner in Advanced Central Lube System