CisoLube Grease Distributor Valve can ensure accurate lubrication, and is suitable for all kinds of harsh conditions, is a perfect lubricant distribution solution. The lubrication distributor includes block-type distributors, slice-type distributors, dual-line distributors, and grease metering valves, which can meet the needs of various types of lubrication systems.

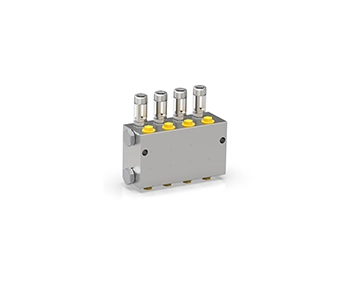

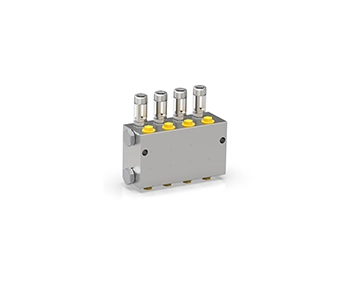

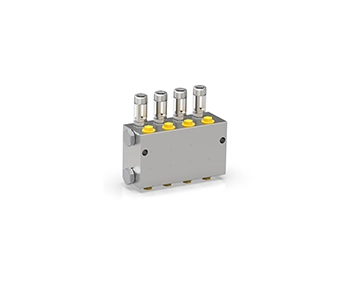

SSV Distributor Valve

SSV Distributor Valve

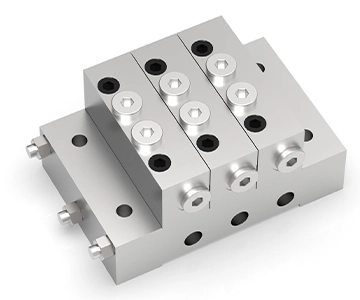

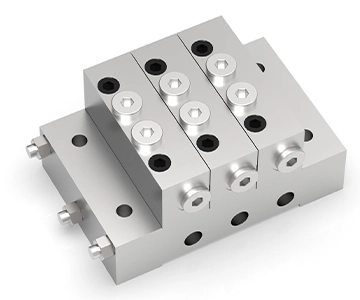

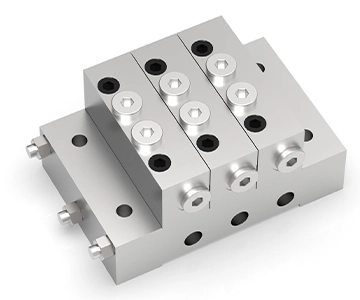

MXF Progressive Distributor Valve

MXF Progressive Distributor Valve

SSVD Distributor Valve

SSVD Distributor Valve

VL-1 Metering Valves

VL-1 Metering Valves

VL-1X Metering Valves

VL-1X Metering Valves

VL-32 Metering Valves

VL-32 Metering Valves

DSKH Metering Devices

DSKH Metering Devices

DSG Dual-line Grease Metering Devices

DSG Dual-line Grease Metering Devices

DSL Dual-line Metering Devices

DSL Dual-line Metering Devices

VB Distributor Valve

VB Distributor Valve

VSP Distributor Valve

VSP Distributor Valve

DU Distributor Valve

DU Distributor Valve

DSS Distributor Valve

DSS Distributor Valve

VE Distributor Valve

VE Distributor Valve

B-MV Metering Valves

B-MV Metering Valves

55V Metering Valves

55V Metering Valves

33V Metering Valves

33V Metering Valves

T86 Metering Valves

T86 Metering Valves

VMN Metering Valves

VMN Metering Valves

SSV Distributor Valve

SSV Distributor Valve

MXF Progressive Distributor Valve

MXF Progressive Distributor Valve

SSVD Distributor Valve

SSVD Distributor Valve

VL-1 Metering Valves

VL-1 Metering Valves

VL-1X Metering Valves

VL-1X Metering Valves

VL-32 Metering Valves

VL-32 Metering Valves

DSKH Metering Devices

DSKH Metering Devices

DSG Dual-line Grease Metering Devices

DSG Dual-line Grease Metering Devices

DSL Dual-line Metering Devices

DSL Dual-line Metering Devices

VB Distributor Valve

VB Distributor Valve

VSP Distributor Valve

VSP Distributor Valve

DU Distributor Valve

DU Distributor Valve

DSS Distributor Valve

DSS Distributor Valve

VE Distributor Valve

VE Distributor Valve

B-MV Metering Valves

B-MV Metering Valves

55V Metering Valves

55V Metering Valves

33V Metering Valves

33V Metering Valves

T86 Metering Valves

T86 Metering Valves

VMN Metering Valves

VMN Metering Valves

SSV Distributor Valve

SSV Distributor Valve

MXF Progressive Distributor Valve

MXF Progressive Distributor Valve

SSVD Distributor Valve

SSVD Distributor Valve

VL-1 Metering Valves

VL-1 Metering Valves

VL-1X Metering Valves

VL-1X Metering Valves

VL-32 Metering Valves

VL-32 Metering Valves

DSKH Metering Devices

DSKH Metering Devices

DSG Dual-line Grease Metering Devices

DSG Dual-line Grease Metering Devices

DSL Dual-line Metering Devices

DSL Dual-line Metering Devices

VB Distributor Valve

VB Distributor Valve

VSP Distributor Valve

VSP Distributor Valve

DU Distributor Valve

DU Distributor Valve

DSS Distributor Valve

DSS Distributor Valve

VE Distributor Valve

VE Distributor Valve

B-MV Metering Valves

B-MV Metering Valves

55V Metering Valves

55V Metering Valves

33V Metering Valves

33V Metering Valves

T86 Metering Valves

T86 Metering Valves

VMN Metering Valves

VMN Metering Valves

A grease distributor block works by controlling the flow of fluid in a hydraulic system. It typically consists of a housing with multiple ports and internal passages. Inside the grease distributor valve, there is a spool or rotor that can be rotated or slid to different positions. When the spool or rotor is moved, it aligns with specific ports or passages, allowing fluid to flow through them. By directing the flow of fluid to different sections or components of the hydraulic system, the grease distributor valve enables precise control and operation. The movement of the spool or rotor is typically controlled manually or through a solenoid-operated mechanism.

When selecting a grease distributor valve, several key features should be considered. The required flow rate is crucial as it determines the grease distributor valve's capacity to handle the system's fluid flow. The pressure rating is also important as it indicates the maximum pressure the grease distributor valve can withstand. The number of ports on the grease distributor valve determines how many lines or components it can distribute fluid to. The control mechanism, whether manual or solenoid-operated, affects the ease and precision of operation. Lastly, compatibility with the hydraulic fluid being used is essential to ensure the grease distributor valve's longevity and proper functioning.

Cisolube progressive distributors are advanced lubrication systems designed for precise and efficient delivery of grease and oil lubricants in various industrial applications, including construction machinery, agricultural machinery, mining equipment. These distributors ensure that each lubrication point receives the exact amount of lubricant needed, optimizing performance and reducing waste. The progressive design allows for a systematic distribution of lubricant through a series of interconnected outlets, ensuring consistent and reliable lubrication across all critical components.

Cisolube progressive distributors are known for their robust construction, capable of withstanding harsh operating conditions such as extreme temperatures and heavy mechanical loads. They are compatible with a wide range of lubricants, making them versatile for different machinery and operational requirements. These systems often feature monitoring capabilities, enabling real-time tracking of lubricant levels and performance, which facilitates proactive maintenance and reduces downtime. Overall, Cisolube progressive distributors enhance equipment longevity, minimize wear and tear, and contribute to the efficiency and reliability of industrial operations.

More centralized grease lubrication system details

CISO-Your Partner in Advanced Central Lube System