The Demand for High-Quality Lubrication System in Wind Energy

Wind energy equipment is typically installed in high-altitude areas and operates for extended periods. Given the long-term high-speed operation of these machines, the demand for high-quality lubrication equipment is significant. The progressive lubrication system and dual line lubrication systems must withstand high temperatures and pressures, resist shock, and be capable of remote monitoring to effectively reduce maintenance costs.

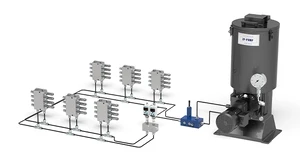

CisoLube GT PLUS Lubrication Pump: A Solution for Wind Energy Equipment

Our GT PLUS lubrication pump meets these demands. It is designed to withstand high temperatures and pressures, and its robust construction offers strong shock resistance. The lubricating pumps can be remotely monitored, which significantly reduces the maintenance costs of wind energy equipment. GT PLUS lubrication pump with hydraulic oil disk design, can ensure that the GT Plus auto lube pump in the wind power equipment in the process of high-speed rotation, the oil in the pump does not overflow, can be normal pumping oil, wind power equipment parts for accurate lubrication.

Application of Lubrication System in Wind Energy Equipment

Our lubrication products are applicable to various components of wind energy equipment. These include the pitch bearing, main shaft bearing, yaw bearing, pitch bearing drive, yaw bearing drive, and the generator. By ensuring these critical components are adequately lubricated, the lifespan of the equipment can be extended, and the overall efficiency of the wind energy system can be improved.

In conclusion, CisoLube Centralized lubrication system, particularly the GT PLUS lubrication pump, provide an effective and efficient solution for the demanding lubrication needs of wind energy equipment.

Lubrication Points for Wind Turbines

Wind turbine lubrication systems are essential for maintaining the efficiency and longevity of wind turbines. Key lubrication points include the main shaft, gearbox, yaw and pitch bearings, and generator bearings. Proper lubrication minimizes friction and wear, ensuring smooth operation and reducing maintenance costs. Wind turbine lubrication systems often use automated dispensers to deliver precise amounts of lubricants at regular intervals. High-quality lubricants designed for extreme conditions are crucial to withstand varying temperatures and heavy loads. Regular monitoring and maintenance of the wind turbine lubrication system enhance performance and reliability, ultimately maximizing energy production and minimizing downtime.

How to Choose Right Wind Turbine Lubrication System

Choosing the right wind turbine lubrication system is crucial for optimal performance and longevity. Start by considering the specific lubrication requirements of your turbine, including the main shaft, gearbox, yaw and pitch bearings, and generator bearings. Evaluate the operating conditions such as temperature, load, and environmental factors. Opt for a system that offers automated lubrication to ensure consistent delivery of lubricants, reducing manual intervention and maintenance costs. High-quality lubricants that can withstand extreme conditions and prevent oxidation are essential.

Consider systems with monitoring capabilities to track lubricant levels and performance, enabling proactive maintenance. Compatibility with existing equipment and ease of installation are also vital factors. Research brands known for reliability and after-sales support. Assess the total cost of ownership, including initial investment, maintenance, and potential downtime savings. Consulting with experts and reviewing case studies can provide valuable insights. A well-chosen wind turbine lubrication system enhances efficiency, reduces wear, and ensures long-term reliability.

Contact CisoLube for Centralised Grease Lubrication System

CN

CN

EN

EN

ru

ru  fr

fr  de

de  es

es  pt

pt  ar

ar  hi

hi  id

id  tr

tr