Agricultural machinery often operates under harsh environmental conditions, such as high temperature, high humidity, and flying dust. These conditions place high demands on the lubrication performance of bearings and chains. Ciso lubrication system can customize professional lubrication solutions for all types of agricultural machinery.

Agricultural machinery often operates under harsh environmental conditions, such as high temperature, high humidity, and flying dust. These conditions place high demands on the lubrication performance of bearings and chains. Ciso lubrication system can customize professional lubrication solutions for all types of agricultural machinery.

Challenges of Lubricating Construction Machinery

Construction machinery, including bulldozers, excavators, loaders, and mining trucks, operates under challenging conditions with numerous lubrication points that are widely distributed. These machines often face harsh environments, including rough terrain and outdoor operations, making maintenance difficult and time-consuming. To ensure reliable performance and extended equipment lifespan, a robust and efficient lubrication system is essential.

Challenges of Lubricating Construction Machinery

Construction machinery, including bulldozers, excavators, loaders, and mining trucks, operates under challenging conditions with numerous lubrication points that are widely distributed. These machines often face harsh environments, including rough terrain and outdoor operations, making maintenance difficult and time-consuming. To ensure reliable performance and extended equipment lifespan, a robust and efficient lubrication system is essential.

Mining machinery typically requires continuous operation, making lubrication work indispensable. Lubrication equipment must withstand high temperatures, pressure, and be explosion-proof for extended periods. Lubrication should occur during equipment operation. Our GP212 and ZP series lubrication pumps, made of special metal materials, effectively withstand high temperatures and pressures, provide explosion protection, and allow lubrication time setting based on working conditions, ensuring continuous and efficient lubrication.

Mining machinery typically requires continuous operation, making lubrication work indispensable. Lubrication equipment must withstand high temperatures, pressure, and be explosion-proof for extended periods. Lubrication should occur during equipment operation. Our GP212 and ZP series lubrication pumps, made of special metal materials, effectively withstand high temperatures and pressures, provide explosion protection, and allow lubrication time setting based on working conditions, ensuring continuous and efficient lubrication.

Oil equipment is often installed in harsh environments, such as offshore platforms and oil fields, making maintenance difficult and costly. Our GT series products can set operating times, automatically control lubricant discharge for each line, achieve automatic lubrication of oil field equipment, and can be connected to wireless devices for remote lubrication monitoring.

Oil equipment is often installed in harsh environments, such as offshore platforms and oil fields, making maintenance difficult and costly. Our GT series products can set operating times, automatically control lubricant discharge for each line, achieve automatic lubrication of oil field equipment, and can be connected to wireless devices for remote lubrication monitoring.

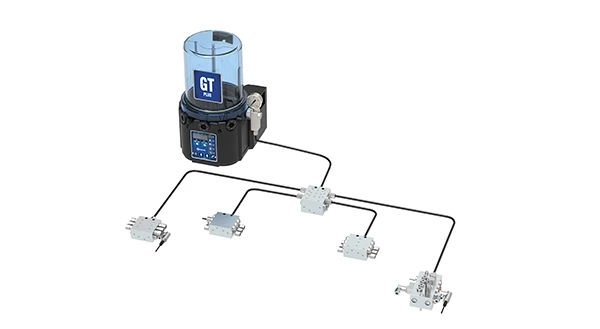

Wind energy machinery, often situated in elevated regions and running for long durations at high velocities, necessitates high-quality lubrication. Our GT PLUS lubrication pump is designed to endure high temperatures and pressures, provide robust shock resistance, allow remote monitoring, and significantly cut down maintenance costs of wind power equipment.

Wind energy machinery, often situated in elevated regions and running for long durations at high velocities, necessitates high-quality lubrication. Our GT PLUS lubrication pump is designed to endure high temperatures and pressures, provide robust shock resistance, allow remote monitoring, and significantly cut down maintenance costs of wind power equipment.

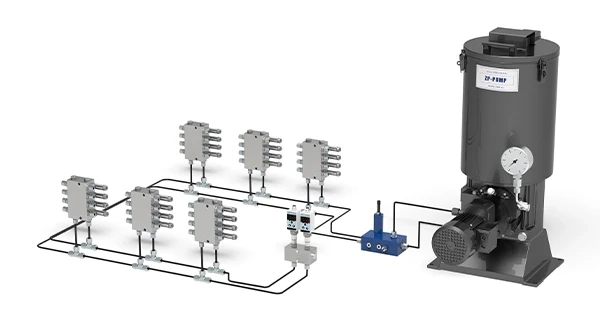

Steel and metallurgical equipment often operates under harsh conditions such as high temperatures, pressures, and loads, requiring a large amount of lubricant. Our ZP series dual-line lubrication system can be installed on key parts of the equipment, such as bearings, gears, and chains, providing lubricant through two lubrication pipelines simultaneously, ensuring sufficient lubrication of the equipment’s key parts.

Steel and metallurgical equipment often operates under harsh conditions such as high temperatures, pressures, and loads, requiring a large amount of lubricant. Our ZP series dual-line lubrication system can be installed on key parts of the equipment, such as bearings, gears, and chains, providing lubricant through two lubrication pipelines simultaneously, ensuring sufficient lubrication of the equipment’s key parts.

Port equipment, typically located in special locations like seashores or docks, is large and requires a lot of lubricant, making maintenance challenging. Our GP212 series products have a large capacity, operate smoothly, produce low noise, have a low failure rate, are easy to install and maintain, and each pump head can easily adjust the flow rate, making them ideal for port equipment.

Port equipment, typically located in special locations like seashores or docks, is large and requires a lot of lubricant, making maintenance challenging. Our GP212 series products have a large capacity, operate smoothly, produce low noise, have a low failure rate, are easy to install and maintain, and each pump head can easily adjust the flow rate, making them ideal for port equipment.

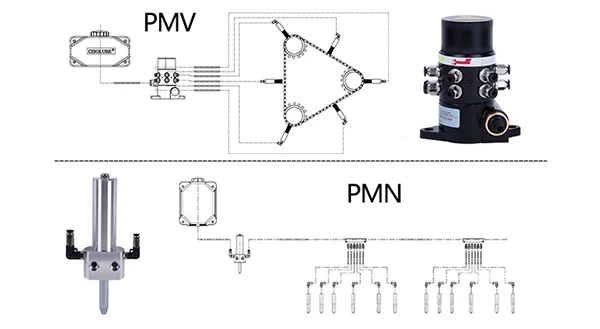

Machine tools, typically composed of multiple components with complex structures and limited installation space, have numerous lubrication points, making lubrication challenging. It’s difficult for lubricants to fully cover each lubrication point, leading to inadequate lubrication. Our GM and GT-MAX series products, with their compact size, are ideal for installation in tight spaces. They can be used in progressive or single-line lubrication systems,meeting complex lubrication needs.

Machine tools, typically composed of multiple components with complex structures and limited installation space, have numerous lubrication points, making lubrication challenging. It’s difficult for lubricants to fully cover each lubrication point, leading to inadequate lubrication. Our GM and GT-MAX series products, with their compact size, are ideal for installation in tight spaces. They can be used in progressive or single-line lubrication systems,meeting complex lubrication needs.

The lubrication of automated equipment requires regular monitoring and maintenance to ensure the quality and supply of lubricants, and to monitor indicators such as viscosity, contamination, and residue. Our GM and GT-MAX series products feature a visual pump body for intuitive monitoring of grease conditions, a front-end distributor filter for effective oil impurity filtration, and an end pressure detection switch for timely feedback on lubrication failures.

The lubrication of automated equipment requires regular monitoring and maintenance to ensure the quality and supply of lubricants, and to monitor indicators such as viscosity, contamination, and residue. Our GM and GT-MAX series products feature a visual pump body for intuitive monitoring of grease conditions, a front-end distributor filter for effective oil impurity filtration, and an end pressure detection switch for timely feedback on lubrication failures.