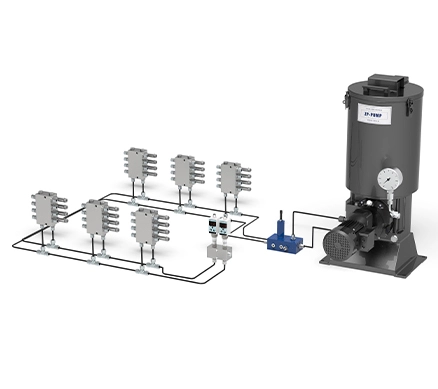

Centralized grease lubrication system is a system that supplies the required lubricant and grease accurately to multiple lubrication points from a lubricant supply source through some distributors and pipelines according to a certain time. Automatic grease lubrication systems can ensure stable lubrication, reduce mechanical wear and prolong the service life of machinery. Automatic lubrication system is usually used in wind power equipment, engineering machinery, agricultural machinery, mining machinery and other industries.

Automatic grease lubrication systems come in various types including Progressive lubrication system, Chain Lubrication Systems, Single Line lubrication system, and Dual-line lubrication systems, and Each type is designed for specific applications, offering efficient lubrication distribution. Choose Cisolube auto lubrication systems company, reducing maintenance costs, and enhancing machinery lifespan.

| Feature | Progressive Lubrication System | Single-line Lubrication System | Dual-line Lubrication System | Chain Lubrication System |

| Definition | Progressive lubrication system is an efficient lubrication system used for mechanical equipment, providing lubricant progressively to different parts of the equipment to ensure each part receives an adequate amount of lubrication. | The lubrication pump automatically delivers lubricant to the lubricant dispenser via a single supply line. Each dispenser serves only one lubrication point and can be adjusted to provide the exact dose of grease or oil required. | Dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump | Chain lubrication system is a system used to protect and maintain chains of mechanical equipment. It works mainly by providing the right amount of lubricant to reduce chain friction and wear, and to maintain chain flexibility and operating efficiency. A chain lubrication system usually includes a tank, lines, and brushes. These components work together to ensure that the chain surface is always properly lubricated, prolonging the life of the chain and drive system, reducing maintenance costs, and improving equipment reliability and efficiency. |

| Basic Components | A —GT lubrication pump B —GM lubrication pump 1 —Outlet relief valve elements 2 —Main line 3 —Filter 4 —pressure switch 5 —progressive distributor(1generation) 6 —progressive distributor(2generation) 7 —progressive distributor(2generation) 8 —progressive distributor(3generation) 9 —Function control 10 —Fault Monitoring 11 —Pipes and hoses 12 —Line to the lubrication point 13 —Controller | A — GT-MAX B — GMS PUMP 1 — Return solenoid valve assembly 2 — Pressure gauge 3 — Pipelines 4 — Filter 5 — Tee branching pleces 6 — Pipe clamps 7 — Four branching pleces 8 — Volumetric distributor 9 — Check device(pressure switch) 10 — Line to the lubrication point 11 — Controller | A、ZP01/02 Lubrication Pump B、ZP08/14/24 Lubrication Pump 1、DSG Dual-line Metering Devices 2、DSL Dual-line Metering Devices 3、DSKH Metering Devices 4、WP-C Electric Change-Over Valve5、DU-C Hydraulic Change-Over Valves 6、MC-ⅠSystem Control Box 7、EPW End-of-line Pressure Switches | A、PMV Chain Lubrication Pump B、PMN Chain Lubrication Pump 1、Oil Tank 2、Brushes 3、High-Pressure Flexible Pipe |

| Working Principle | The lubricant is pumped through the main lines to the progressive distributor with the pump. The lubricant is elivered "progressively" to the friction point. The circulation of a progressive distributor is monitored optically or electrically. | The dosing values are impinged on the main line with the pump – dynamically operating metering valves with a pressure surge, static operating dosing elements with slow pressure build-up. These thus transfer the respective quantity of the lubricant to the friction point.During the following relief phase, the lubricant is restacked in the dosing valves for the next lubrication process. | CISO dual-line systems can be used on large systems with dispersed lubrication points that require varying lubrication quantities. These systems utilize two main lines that are supplied alternately with lubricant from a high-pressure pump via a change-over valve at up to 400 bar (5 800 psi) Branch lines, along the main lines, are connected with dual-line metering devices to supply a large volume of lubricant to the lubrication points Within large dual-line systems, end-of-line pressure switches are used to control and monitor the system. | The chain lubrication system transfers the lubricant from the storage tank to the brushes through the lubrication pump, and through the brushes the lubricant is applied to the chain to form a lubricating film, which reduces the chain friction and wear. |

| Advantages | - Compact, flexible kit - Monitored function - Channels flow through completely - Wide range of use | Connecting numerous lubrication points - Smallest dosing quantities - Compact construction - For oil or fluid grease - Low cost and high efficiency - Easy assembly | • Reliable• Simple to service• Ultrasonic low- and high-level control options• Built-in lubricant filter | Compact structure and easy expansion - No need for a distributor - The pipes are smooth and have no residue - Adjustable displacement |

This type of centralised lubrication system involves using a grease gun or oil can to manually apply lubricant to the moving parts of the equipment.

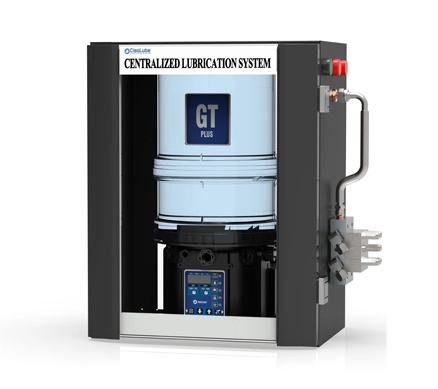

An electric lubrication system is a centralised lubrication system that automatically delivers lubricating oil or grease from a centralized storage tank through dispensers and piping, driven by an electric pump, to the parts of the equipment that require lubrication.

A pneumatic lubrication system is a centralised lubrication system that utilizes gas pressure to transfer lubricant or grease to the friction areas of mechanical equipment.

Reduced equipment downtime: Proper oil pump lubrication systems help prevent wear and reduces equipment downtime. Wear can lead to equipment failures and expensive repair costs.

Extended equipment lifespan: Oil pump lubrication systems help protect equipment from wear, extending its lifespan and reducing the need for frequent replacements.

Improved safety: Proper oil pump lubrication systems reduce the risk of equipment failures, which can lead to workplace accidents and injuries.

With Cisolube lubrication system manufacturer, oil pump lubrication systems are crucial for ensuring efficient and safe operations. Cisolube centralized grease lubrication systems help reduce equipment downtime, extend equipment lifespan, and improve workplace safety. By investing in well-designed automatic grease lubrication systems, manufacturing companies can significantly enhance productivity and profitability.

CISO-Your Partner in Advanced Central Lube System